Working with polypropylene sheet for the first time often presents new challenges for thermoformers including shrinkage, low rigidity, and low stiffness. The addition talc or calcium carbonate mineral fillers can help remedy these problems while contributing added benefits compared to resin-only formulations. Adding talc as a mineral filler enhances properties such as stiffness, thermal stability, and wear resistance by acting as a reinforcing agent and nucleating agent in the polypropylene matrix. But while talc and calcium carbonate both offer benefits, we often find our customers asking, “what’s the difference?”

Working with polypropylene sheet for the first time often presents new challenges for thermoformers including shrinkage, low rigidity, and low stiffness. The addition talc or calcium carbonate mineral fillers can help remedy these problems while contributing added benefits compared to resin-only formulations. Adding talc as a mineral filler enhances properties such as stiffness, thermal stability, and wear resistance by acting as a reinforcing agent and nucleating agent in the polypropylene matrix. But while talc and calcium carbonate both offer benefits, we often find our customers asking, “what’s the difference?”

When considering the use of a mineral filler, increased stiffness, increased rigidity, heat deflection, and cost are typically of concern to our customers. But what minerals or combination of minerals should you use to achieve desired part function? This answer of course varies from case to case depending on the end use application and desired properties – but to make things a bit easier, we have outlined the tradeoffs and benefits that come as a result of using these mineral fillers in PP sheet. Polypropylene is a member of the polyolefins family, derived from the propylene monomer, and is valued for its chemical resistance, versatility, and lowest density among commodity plastics, making it lightweight and cost-effective.

Mineral Structure

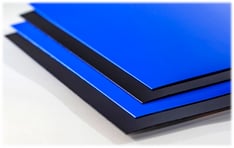

To start, the structure of each mineral has a drastic impact on how it behaves when added to plastic, impacting the properties of the sheet and as a result, the formed part. Talc has a plate-like structure, which means that when extruded, the plates will orient in the direction of extrusion. Talc consists of layered, plate-like mineral structures, which contribute to its effectiveness as a reinforcing agent. This mineral structure results in increased rigidity and resistance to heat. The form and alignment of talc platelets influence the mechanical behavior and crystallinity of the polypropylene sheet, enhancing stiffness and thermal properties. Calcium carbonate has more of a spherical or cube shape. The addition of calcium carbonate will increase stiffness, but not as much as in talc filled polypropylene sheet.

PP/talc compounds are typically prepared using a twin screw extruder to ensure good dispersion of the talc filler, and test specimens are often injection moulded to achieve uniformity for mechanical and thermal property evaluation.

Impact Strength

While the plate-like structure of talc contributes to increased rigidity and heat resistance, it results in a significant decrease in impact strength. Talc-filled polypropylene can suffer from reduced elongation at break and lower toughness due to stress concentrations around talc particles. The mechanical properties, such as impact strength and elongation at break, are determined by the dispersion and interaction of the talc filler within the polymer matrix. Calcium carbonate, however, does not have an adverse affect on impact strength. In fact, in studies conducted by Heritage Plastics, calcium carbonate was found to improve this property at higher loading levels.

This increase in impact strength ultimately allows for a more durable part: “The significant finding here is that CaCO3 can be used at levels up to 35% by weight in polypropylenes without adversely affecting impact strength. This finding will be key in maintaining performance in parts with reduced wall thickness when switching from resin only systems to formulations that contain calcium carbonate.” (Holly Hansen, Heritage Plastics)

The influence of talc on Young's modulus, toughness, and volume resistivity is often evaluated through standardized tests, where the way stress is carried and how the material responds to impact or crack propagation is carefully measured.

Heat Deflection

Despite the sacrifice of impact resistance when using talc, heat deflection, or thermal conductivity, of the talc allows it to cool faster reducing shrinkage in formed parts. The effect of talc on crystallinity and heat deflection temperature is influenced by the compound preparation and processing conditions. Reduced shrinkage can significantly help with the predictability and appearance of the formed part. Polypropylene’s lowest density among commodity plastics contributes to its lightweight and cost-effective nature. Calcium carbonate is also able to combat temperature changes in PP sheet, with higher loading being more efficient than lower loading, although to a lesser extent than talc.

The mold cooling rate and the use of talc filler can influence the dimensional stability and surface quality of injection moulded parts, as talc-filled polypropylene cools faster in the mold and reduces sink marks.

Since this property is increased with both minerals, it comes as no surprise that a blend of the two produced the best results: “Coefficient of Linear Thermal Expansion or CLTE monitors the expansion and contraction of the part as it undergoes thermal changes. Talc with its platy structure is much more efficient in minimizing expansion and contraction of the final part due to temperature changes. However, calcium carbonate is also able to suppress temperature related changes in polypropylene. Higher mineral loads were more efficient than lower loadings. And blends of the two minerals were extremely effective in reducing thermal changes.” (Holly Hansen, Heritage Plastics)

Chemical additives and stabilizers are often used in these compounds to prevent polymer degradation and thermal degradation during processing and use, thereby enhancing long-term chemical resistance and durability.

Final Thoughts

As with every application, it all depends on what you’re trying to accomplish when deciding what mineral to use. Both talc and calcium carbonate will reduce shrinkage during thermoforming; both minerals will increase rigidity; both minerals will increase heat deflection temperature, with talc being the most effective. If stiffness is your main concern, then talc is the way to go, but if you’re worried about impact resistance, calcium carbonate filled polypropylene sheet is the clear choice. The conclusions from various studies and articles indicate that while talc filler improves stiffness and heat resistance, it may negatively affect impact strength and ductility. The overall performance of talc-filled polypropylene is also affected by the use of additives, which can optimize the interface contact and chemical stability of the compound. Further information and technical details can be found in academic articles and references on polypropylene composites.

Introduction to Filled Polypropylene

Filled polypropylene represents a significant advancement in applied polymer science, offering a way to tailor the properties of polypropylene to meet the demands of a wide range of applications. By incorporating mineral fillers such as talc or calcium carbonate into the polymer matrix, manufacturers can enhance the mechanical properties, heat deflection temperature, and dimensional stability of polypropylene, making it a more versatile and durable material.

Polypropylene, known for its low density and cost-effectiveness, is widely used in packaging, automotive, and consumer goods. However, its inherent limitations—such as lower stiffness, limited thermal resistance, and susceptibility to shrinkage—can restrict its use in more demanding environments. The addition of mineral fillers addresses these challenges by increasing stiffness, improving resistance to heat, and reducing issues like sink marks and warpage in injection-molded or thermoformed parts.

Talc, a platy mineral filler, is especially effective at boosting the Young’s modulus, tensile strength, and overall rigidity of polypropylene. Its unique structure enhances the heat deflection temperature and dimensional stability, making talc-filled polypropylene ideal for applications where mechanical strength and thermal performance are critical. The addition of talc also helps reduce sink marks, resulting in better surface quality and appearance for finished parts.

Achieving optimal performance from filled polypropylene depends on the uniform dispersion of fillers within the polymer matrix. Advanced processing techniques, such as compounding with a twin screw extruder, ensure that fillers are evenly distributed, which is essential for maximizing mechanical and thermal properties. Once compounded, the material can be injection molded or formed into sheets, providing flexibility in manufacturing and design.

The use of mineral fillers not only improves the performance of polypropylene but also offers economic advantages. By partially replacing the polymer with fillers, manufacturers can reduce material costs while maintaining or even enhancing product quality. Filled polypropylene formulations can be customized to achieve specific property targets, allowing for efficient solutions across a broad spectrum of industries.

In summary, filled polypropylene combines the benefits of a lightweight, cost-effective polymer with the enhanced properties provided by mineral fillers. Whether the goal is to increase stiffness, improve heat resistance, or achieve greater dimensional stability, the addition of fillers like talc enables polypropylene to meet the evolving needs of modern plastics applications. As research continues, new blends and processing methods promise to further expand the capabilities and performance of filled polypropylene in the marketplace.