Choosing the right plastic sheet for your application can be confusing, particularly if you are new to the industry. In our blog post, “When it Comes to Material Selection, Not All Plastics are Created Equal,” we gave a quick overview of the polymers that Impact extrudes, touching on their general characteristics and typical uses.

In this next blog post, we narrow our focus to discuss one of the materials we extrude in greater detail – Low Density Polyethylene (LDPE). LDPE is a thermoplastic polymer classified within the polyethylene family, known for its flexibility, durability, and ease of moulding. LDPE is a very versatile plastic and is often used in flexible film and bag applications, but it can also be used to make bottles, food storage containers and rigid trays. Below are 5 important characteristics of LDPE plastic:

-

LDPE has a lower density than other grades of PE:

Low Density Polyethylene is exactly what it sounds like – it is a grade of polyethylene that carries with it a lower density than it’s counterpart, High Density Polyethylene (HDPE).

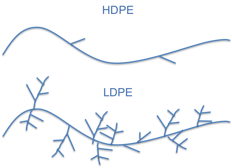

PE is created from the polymerization of ethylene which produces very long, straight chains of hydrocarbon monomers. Ethylene gas is the key raw material in this process, and polymerization links ethylene molecules (each containing two carbon atoms) into long polymer chains. The number of carbon atoms in the monomer unit influences the polymer's properties, resulting in different properties among members of the polyethylene family. Through adjustments to the polymerization process, these chains can be made to branch, and the degree of branching determines the grade of PE that is produced. With LDPE, there is a high degree of branching, which means that the polymer has a less compact molecular structure leading to a lower density and greater flexibility.

-

LDPE is a semi-crystalline polymer:

An important distinction between different thermoplastic polymers is amorphous vs. semi-crystalline. LDPE is a semi-crystalline polymer which means that regions of the material exhibit organized and tightly packed molecular chains. The areas of crystallinity are called spherulites and can vary in shape and size with amorphous areas existing between the crystalline areas. The degree of crystallinity affects many characteristics of the polymer. Because of the highly branched structure of LDPE, this polymer has low crystalline and high amorphous regions. These characteristics result in a lower density and a softer and more flexible product in comparison to HDPE. To offer a basis for comparison, LDPE has a density range of around 0.91-0.94g/cm3 vs. HDPE, which has a density range of 0.95-0.97 g/cm3. LDPE's physical properties include flexibility and transparency, while its chemical properties feature excellent resistance to chemicals and moisture, making it suitable for demanding environments.

-

LDPE is soft and flexible:

As noted above, the increased branching characteristic of LDPE results in a softer and more flexible material in comparison to HDPE. This increased branching leads to irregularly packed molecules and weaker intermolecular bonds, resulting in a lower tensile strength. While LDPE has a lower tensile strength, it has greater ductility, which refers to a solid material’s ability to deform under tensile strength. This means that LDPE can be stretched without breaking. For this reason, LDPE is widely used in products such as plastic bags and films. In addition, the soft and flexible nature of this material also results in a high impact strength. LDPE exhibits notable impact resistance, toughness, and yield stress, which are mechanical properties that differ from other materials. Its melting temperature is lower than that of HDPE, and its flexibility and toughness make it a preferred choice for many packaging applications.

-

LDPE is versatile:

Similarly to HDPE, LDPE is one of the most versatile plastics and has many different uses spanning across various industries – from industrial, to food, to consumer goods. Due to the high ductility of this material, a common application for LDPE is plastic bags. This material has also found a home in food packaging and is often used as a film for baked goods, meat and frozen foods, as well as for liquid packaging such as milk cartons and bag-in-box applications. Impact Plastics customers are currently using LDPE sheet for applications in the medical industry. LDPE is commonly used in industrial applications, medical bags, and tubing, due to its moisture resistance and excellent electrical properties as an insulator. Its versatility, combined with being a cost effective choice and a valuable material for manufacturers, makes LDPE widely adopted across multiple sectors.

-

LDPE is recyclable:

LDPE is recyclable:

LDPE is an easily recyclable material and is collected by many recycling programs across the United States. For recycling purposes, this material is identified by the resin ID code ‘4’, which is important for sorting and processing LDPE during recycling. Uniform distribution of additives or recycled content is important for maintaining product quality in recycled LDPE products. However, the different forms of LDPE packaging (i.e. film and bag vs. rigid), require different recycling channels. Rigid LDPE products such as bottles, containers, caps and lids are typically accepted through your traditional curbside recycling program. Flexible LDPE products, however, can be dropped off at participating retail stores in your area. Plastic Film Recycling, an organization supported by the Flexible Film Recycling Group of the American Chemistry Council, has put together a handy tool that allows you to locate local drop-off centers where you can recycle your clean and dry flexible LDPE products. Acceptable flexible LDPE materials include retail bags, zip-top food storage bags, plastic overwrap, and even plastic cereal box liners.

LDPE is produced using low cost processes that operate at high temperatures, often involving small molecules in both polymerization and recycling stages. While Impact Plastics does not produce LDPE for film and bag applications, we feel that it is important to help spread awareness to consumers and our customers about the recycling options that exist for plastic film so that we can help keep these materials out of nature, and recycle them back into useful applications. According to “Plastics Makes it Possible”, recycled LDPE is currently being used in applications such as shipping envelopes, trash cans and can liners, landscape timber, furniture, and more.

For more information on LDPE and our other polyethylene products, check out our ‘Materials’ section, or click on the button to download our polyethylene material solutions!