The benefits of polypropylene are indisputable – the material efficiency, sustainability attributes, and performance of the polymer result in an extremely versatile material. However, the one drawback that has pushed customers in the direction of other polymers such as PET and Clear HIPS has been clarity – or lack thereof.

The benefits of polypropylene are indisputable – the material efficiency, sustainability attributes, and performance of the polymer result in an extremely versatile material. However, the one drawback that has pushed customers in the direction of other polymers such as PET and Clear HIPS has been clarity – or lack thereof.

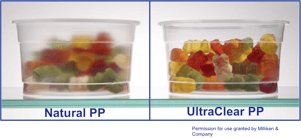

As a semi-crystalline material, polypropylene sheet typically possesses a milky or hazy appearance, making it undesirable for packaging where visual appeal is a high priority - but that was before UltraClear. With UltraClear polypropylene sheet for thermoforming, customers can experience the same level of clarity and aesthetics found in traditional clear polymers such as PET, PVC and Clear HIPS, while taking advantage of the cost efficiency, functional properties and sustainability attributes associated with this polymer.

To achieve this, Impact Plastics has partnered with Milliken & Co., the creator of the Millad® NX™ 8000 clarifying additive to produce a high-clarity polypropylene sheet like never before seen in the plastic sheet extrusion industry. Where as clarifiers have been historically integrated into the material at resin production, we integrate the NX™ 8000 additive at the extrusion level. This gives us flexibility in terms of the resin and grade used, allowing us to create a custom formulation for each customer, while offering a 60% clarity improvement over nucleated PP resins.

To achieve this, Impact Plastics has partnered with Milliken & Co., the creator of the Millad® NX™ 8000 clarifying additive to produce a high-clarity polypropylene sheet like never before seen in the plastic sheet extrusion industry. Where as clarifiers have been historically integrated into the material at resin production, we integrate the NX™ 8000 additive at the extrusion level. This gives us flexibility in terms of the resin and grade used, allowing us to create a custom formulation for each customer, while offering a 60% clarity improvement over nucleated PP resins.

With packaging - particularly for food applications - trending towards clear, achieving the right combination of aesthetics and functionality is important – but with UltraClear you get the best of both worlds. A highly versatile material, UltraClear PP is suitable for applications in the food and foodservice packaging, consumer goods and electronics packaging, and medical packaging markets.