So you’ve narrowed down what material you need thanks to our “Learn More About your Plastic Sheet” series - now its time to download a data sheet and take a look at the performance attributes of the materials we carry. But if you’re new to the industry, or don’t work in a technical role, the information stated on material data sheets can leave you more confused than when you started.

So you’ve narrowed down what material you need thanks to our “Learn More About your Plastic Sheet” series - now its time to download a data sheet and take a look at the performance attributes of the materials we carry. But if you’re new to the industry, or don’t work in a technical role, the information stated on material data sheets can leave you more confused than when you started.

If you’ve ever felt this way after reviewing a material data sheet, then this next Impact Plastics Blog series focused on “Understanding your Data Sheet” is for you. In this next blog series we will explore ASTM tests commonly found on material data sheets for thermoplastic resins. Our last post discussed density and specific gravity – now we move onto another commonly encountered specification – Impact Resistance. Continue reading to learn more!

The American Society for Testing and Materials (ASTM) is an organization that defines and sets standards to ensure good quality and workmanship. Over 12,000 ASTM standards operate globally, including tests specific to plastics, to help consumers have confidence that the products they purchase will perform as expected.

The American Society for Testing and Materials (ASTM) is an organization that defines and sets standards to ensure good quality and workmanship. Over 12,000 ASTM standards operate globally, including tests specific to plastics, to help consumers have confidence that the products they purchase will perform as expected.

One of the ASTM test methods for plastic commonly seen on data sheets is a test for impact resistance. This test is often seen with the designation ASTM D256 and is referred to as “Notched Izod Impact Strength.” The use of this test can be a quick and easy quality control check to determine if a material complies with certain impact requirements or to compare toughness from material to material. A material’s toughness is a factor of its ability to absorb energy during plastic deformation. Brittle materials, for example, have low toughness as a result of the minimal amount of deformation they can endure. Impact toughness of a given material can also be impacted by temperature changes – in general, impact toughness decreases the lower the temperature gets.

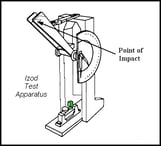

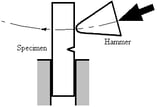

The Notched Izod Impact test is a single point test that measures a materials resistance to impact from a swinging pendulum. Izod impact is defined as the kinetic energy needed to initiate fracture and continue the fracture until the specimen is broken. The test specimen used in the Notched Izod Impact test are notched to prevent deformation of the specimen upon impact.

The Notched Izod Impact test is a single point test that measures a materials resistance to impact from a swinging pendulum. Izod impact is defined as the kinetic energy needed to initiate fracture and continue the fracture until the specimen is broken. The test specimen used in the Notched Izod Impact test are notched to prevent deformation of the specimen upon impact.

To conduct this test, the notched specimen is clamped into the pendulum impact test fixture with the notched side of the specimen facing the  striking edge of the pendulum. The pendulum is subsequently released allowing it to strike through the specimen. If breakage does not occur, a heavier weight or hammer is added to the pendulum until failure occurs.

striking edge of the pendulum. The pendulum is subsequently released allowing it to strike through the specimen. If breakage does not occur, a heavier weight or hammer is added to the pendulum until failure occurs.

The energy absorbed by the specimen during breakage is known as the breaking energy, and the results are expressed in energy lost per unit of thickness at the notch (ft-lb or J/cm), or as energy lost per unit cross-sectional area at the notch (J/m^2 or ft-lb/in^2), indicating a given material’s impact resistance. ASTM D256 requirements dictate that a minimum of five individual data points be collected to determine the average impact resistance for a particular material. The higher the value the tougher the material.

Since many thermoplastic materials exhibit lower impact strength at reduced temperatures, this test is often conducted at lower temperatures to simulate the intended end-use environment of the material. To conduct this test at low temperatures, the specimens are conditioned at the specified temperature in a freezer, quickly removed, and impacted one at a time.

Do you have a packaging project that requires some guidance on materials? Visit our website and learn more about our materials or get in touch with our sales team today!